love: Love Controller Driver Support

Release 3-2-3

David Kline

June 2006

License Agreement

This product is available via the open

source license described at the end of this document.

Overview

This module is part of synApps to provide support for the Love

Controllers. It consists of MEDM screens, an Asyn-based multi device

port driver, and a database. The MEDM screens provide a way for

viewing the controller values as well as controlling some of its

configuration. The port driver binds generic Asyn device support for

EPICS records with the Asyn serial port driver (drvAsynSerialPort).

The database defines EPICS records, that read/write controller values

and configuration settings.

The Love Controller is an

instrument that can be used to monitor temperature, pressure, serve

as a thermocouple, or control pressure, flow, humidity, motion, or pH

given the proper hardware. The control functions, such as selecting

the input type (voltage, current, etc.), are programmed from the

front panel. Communication with the controller is a half-duplex,

multi drop, RS-485 serial bus. Refer to the documentation for

additional information about the features and programmability of the

instrument. There are several controller models available providing

different options and features, however, this software supports

models 16A and 1600.

Files

The files listed below are the primary ones in the

identified directory.

|

.

|

|

start_epics_love

|

Main MEDM screen startup.

|

|

./documentation

|

|

devAsynLoveCrossTraining.ppt

|

Power point presentation given during a BCDA group meeting.

|

|

devAsynLove.ppt

|

Power point presentation given during the EPICS collaboration

meeting in Spring of 2005 (click

here).

|

|

loveDriver.html

|

This document.

|

|

loveKnownIssues.html

|

List of known issues for each release.

|

|

loveReleaseNotes.html

|

Notes for current and previous releases.

|

|

WIRING

|

Diagram for wiring the controllers and other information.

|

|

./documentation/1600

|

|

1600_Calibration.pdf

|

Calibration document for the 1600.

|

|

1600_CommProtocol.pdf

|

Communication protocol/commands for the 1600.

|

|

1600_Documentation.pdf

|

Users manual.

|

|

./documentation/16A

|

|

16A_Calibration.pdf

|

Calibration document for the 16A.

|

|

16A_CommDoc.pdf

|

Communication protocol/commands for the 16A.

|

|

16A_CommProtocol.pdf

|

Instructions about how to write your own application to

communicate with the 16A.

|

|

16A_DataSheet.pdf

|

General information.

|

|

16A_Documentation.pdf

|

Users manual.

|

|

16A_FlowChart.pdf

|

Programming flow chart.

|

|

./documentation/485LDRC

|

|

485LDRC_Connections.gif

|

Wiring diagram.

|

|

485LDRC_Datasheet.pdf

|

General information.

|

|

485LDRC_Dimentions.gif

|

Installation diagram.

|

|

./iocBoot/ioclove

|

|

st.cmd.linux

|

Startup script for Linux-based IOCs.

|

|

st.cmd.vx

|

Startup script for vxWorks-based IOCs.

|

|

./loveApp/Db

|

|

LoveControllerControl.db

|

PVs for setting controller configuration.

|

|

LoveController.db

|

PVs for reading information from the controller.

|

|

Love_settings.req

|

Request file for auto save/restore.

|

|

./loveApp/op/adl

|

|

LoveController.adl

|

Main read back screen.

|

|

LoveControllerControl.adl

|

Displays additional read back and configuration information.

|

|

LoveControllerFanout.adl

|

Displays PV and rate information.

|

|

./loveApp/src

|

|

drvLove.c

|

Asyn-based multi device port driver.

|

|

loveAppCommonInclude.dbd

|

Basic database definition from base, Asyn, and for Love

controller support.

|

|

loveAppInclude.dbd

|

Primary database definition file.

|

|

loveAppVXInclude.dbd

|

vxWorks-specific database definition file.

|

|

devLove.dbd

|

Necessary for other components to import Love Controller

support.

|

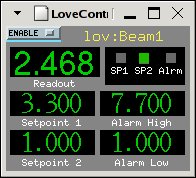

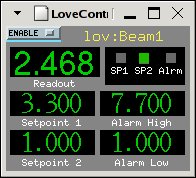

MEDM Screens

When the script 'start_epics_love' is executed, the main

controller screen is displayed (see below). It displays the values

that are of most interest to the user. These values include the read

back, set points, alarm limits, and indicates whether the controller

is in alarm. The 'ENABLE' menu provides a means for

disabling/enabling record processing. When disabled the records will

not be processed and no data acquisition will be performed.

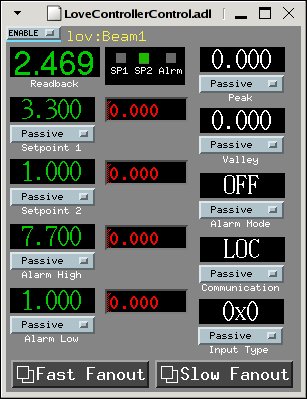

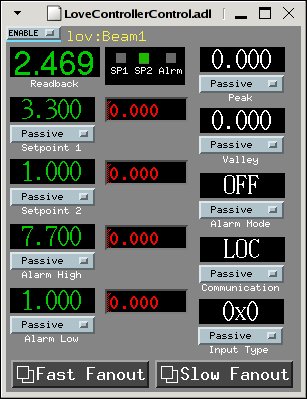

A

hidden menu is available in the upper right hand corner of the main

screen. It displays additional values, such as input type and

communication status, as well as allows one to make adjusts to some

of the configuration parameters (i.e. set point 1 and scan rate). The

display is illustrated below.

Additionally,

the “Fast Fanout” or “Slow Fanout” message

buttons launch other screens that list which PVs are being acquired

and at what rate. The user can enter additional PVs or change the

data acquisition rate. Furthermore, it should be noted that once the

IOC is rebooted, the fanout records will be reset to the original

PVs. These displays are illustrated below. The corresponding database

records require modification to preserve any changes made at runtime.

drvLove

The drvLove is a multi device port driver that binds standard

EPICS device support with the underlying serial bus. It allows a

virtual connection to an individual controller to provide a means for

debugging the communication. The asynRecord can be used to select the

tracing masks for debugging communication.

The driver

implements the asynDrvUser, asynCommon, asynInt32, and

asynUInt32Digital interfaces.

asynDrvUser – Describes the

methods to allow an asynUser to communicate user specific

information to/from the port driver.

asynCommon – Describes the

methods that must be implemented by drivers for reporting driver

information and how to connect or disconnect from the driver.

asynInt32 – Describes the

methods that use integers for communicating with a device.

asynUInt32Digital –

Describes the methods for communicating via bits of an Int32

register.

Database

The database consists of

records for processing data received by the controllers. Records are

categorized as base, composite, and rate. Base records provide

integer-based values that are read from a controller and include

values such as the number of decimal points, set point 1 and 2, alarm

high and low, and status. Composite records take as input base

records to derive floating point representations of the values. For

example, set point 1 is a calc record that receives as input the

decimal points and the set point record values, then uses its CALC

equation to determine the final floating point set point value. By

default, both the base and composite records are process passive and

are processed using fanout records. The fanout records are used to

“drive” the processing rate of the base and composite

records. At the moment there are two fanout records for fast and slow

record processing, their scan rates can be adjusted from MEDM screens

. Note that the “getDecpts” PV must be in the

“Fast” fanout record at all times. This value is required

since it is used by many PVs to derive their floating point value.

Operation

The driver is initialized during IOC startup by calling the

drvLoveInit method passing the driver name (i.e. “LO”)

and the name of the serial port. The initialization method first

connects with the serial port name and finds the asynOctet interface.

Then it registers the port driver name with Asyn and the interfaces

it supports (i.e. asynDrvUser, asynCommon, asynInt32, and

asynUInt32Digital). The port driver must be made aware of the

controller models on the serial bus. To do this the startup script

calls the drvLoveConfig method passing the port driver name (i.e.

“LO”), the controller address (i.e. 1..256), and the

controller model string (i.e. “16A” or “1600”).

After this, the database can be loaded creating the record instances

that support the controllers.

Prior to initializing the

driver, Asyn and the underlying serial bus must be initialized. Refer

to the target-specific startup script located in the iocBoot

directory for details related to initialization.

License Agreement

Copyright (c) 2004 University of Chicago and the Regents of the University of

California. All rights reserved.

synApps is distributed subject to the following license conditions:

SOFTWARE LICENSE AGREEMENT

Software: synApps

Versions: Release 4-5 and higher.

1. The "Software", below, refers to synApps (in either source code, or

binary form and accompanying documentation). Each licensee is addressed

as "you" or "Licensee."

2. The copyright holders shown above and their third-party licensor's hereby

grant Licensee a royalty-free nonexclusive license, subject to the

limitations stated herein and U.S. Government license rights.

3. You may modify and make a copy or copies of the Software for use within

your organization, if you meet the following conditions:

1. Copies in source code must include the copyright notice and this

Software License Agreement.

2. Copies in binary form must include the copyright notice and this

Software License Agreement in the documentation and/or other

materials provided with the copy.

4. You may modify a copy or copies of the Software or any portion of it, thus

forming a work based on the Software, and distribute copies of such work

outside your organization, if you meet all of the following conditions:

1. Copies in source code must include the copyright notice and this

Software License Agreement;

2. Copies in binary form must include the copyright notice and this

Software License Agreement in the documentation and/or other

materials provided with the copy;

3. Modified copies and works based on the Software must carry

prominent notices stating that you changed specified portions of

the Software.

5. Portions of the Software resulted from work developed under a

U.S. Government contract and are subject to the following license:

the Government is granted for itself and others acting on its behalf a

paid-up, nonexclusive, irrevocable worldwide license in this computer

software to reproduce, prepare derivative works, and perform publicly and

display publicly.

6. WARRANTY DISCLAIMER. THE SOFTWARE IS SUPPLIED "AS IS" WITHOUT WARRANTY OF

ANY KIND. THE COPYRIGHT HOLDERS, THEIR THIRD PARTY LICENSORS, THE UNITED

STATES, THE UNITED STATES DEPARTMENT OF ENERGY, AND THEIR EMPLOYEES: (1)

DISCLAIM ANY WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO

ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, TITLE OR NON-INFRINGEMENT, (2) DO NOT ASSUME ANY LEGAL LIABILITY

OR RESPONSIBILITY FOR THE ACCURACY, COMPLETENESS, OR USEFULNESS OF THE

SOFTWARE, (3) DO NOT REPRESENT THAT USE OF THE SOFTWARE WOULD NOT

INFRINGE PRIVATELY OWNED RIGHTS, (4) DO NOT WARRANT THAT THE SOFTWARE WILL

FUNCTION UNINTERRUPTED, THAT IT IS ERROR-FREE OR THAT ANY ERRORS WILL BE

CORRECTED.

7. LIMITATION OF LIABILITY. IN NO EVENT WILL THE COPYRIGHT HOLDERS, THEIR

THIRD PARTY LICENSORS, THE UNITED STATES, THE UNITED STATES DEPARTMENT OF

ENERGY, OR THEIR EMPLOYEES: BE LIABLE FOR ANY INDIRECT, INCIDENTAL,

CONSEQUENTIAL, SPECIAL OR PUNITIVE DAMAGES OF ANY KIND OR NATURE,

INCLUDING BUT NOT LIMITED TO LOSS OF PROFITS OR LOSS OF DATA, FOR ANY

REASON WHATSOEVER, WHETHER SUCH LIABILITY IS ASSERTED ON THE BASIS OF

CONTRACT, TORT (INCLUDING NEGLIGENCE OR STRICT LIABILITY), OR OTHERWISE,

EVEN IF ANY OF SAID PARTIES HAS BEEN WARNED OF THE POSSIBILITY OF SUCH

LOSS OR DAMAGES.